Qualities Policies

Quality is an integral part of our principle . Those principle guides our action to deliver the product that are safe , compliant and preferred by consumers. We strive to achieve the highest standards and aim to be one of the leading companies in the world of pharmaceutical.

Quality control plays a vital role in ensuring that every pharmaceutical product manufactured meets the highest standards of safety, efficacy, and compliance. QC is responsible for verifying the quality of raw materials, in-process samples, packaging components, and finished products through scientifically validated testing methods.

Quality Control

The common activities performed by a Quality Control QC Department Activities

Raw Material Testing

Sampling and analysis of raw materials before use in production.

Verification against pharmacopeial standards or in-house specifications.

In-Process Quality Control (IPQC)

- Monitoring critical stages during manufacturing.

- Checking parameters like weight variation, hardness, friability, disintegration, etc. (for pharma).

Finished Product Testing

- Sampling and testing of final products to ensure they meet defined quality standards before release.

- Stability studies to ensure product shelf life.

Documentation & Records

Preparing and maintaining test reports, CoA (Certificate of Analysis), and logbooks.

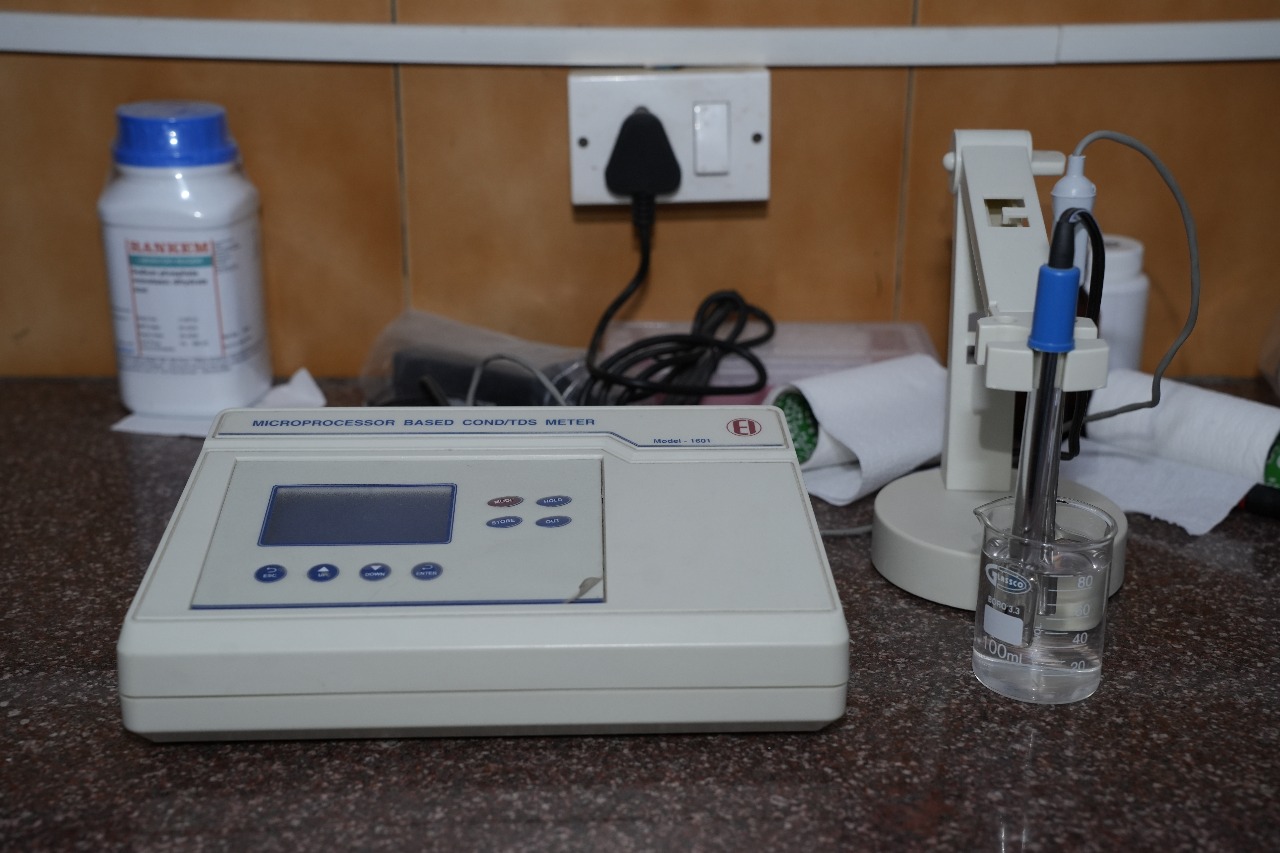

Calibration & Validation

Routine calibration of instruments (HPLC, UV, FTIR, balances, etc.).

- Environmental Monitoring (for pharma/sterile units)

- Checking microbiological quality of air, water, and surfaces.

- Monitoring cleanrooms for particulate matter and microbial load.

- Compliance & Regulatory Support

- Ensuring adherence to GMP, GLP, and regulatory guidelines.

- Assisting during audits and inspections.

- Deviation & OOS Handling

- Investigating Out of Specification (OOS), Out of Trend (OOT), and deviations.

- Implementing corrective and preventive actions (CAPA).

- Training & Awareness

- Training staff in quality procedures, safety, and hygiene.

- Updating SOPs (Standard Operating Procedures).

- Release of Materials & Products

- QC issues approval/rejection